|

| | | |

|  | | |

|

Untitled Document | APL Specification 5L/ISO 3183

Table 4 --Chemical composition for PSL 1 pipe with 25,0 mm (0.984 in)

Steel grade

(Steel name) | Mass fraction, based upon heat and product analyses a

% | C

max.b | Mn

max.b | P

| S

max. | V

max. | Nb

max. | Ti

max. |

min. |

max. | | Seamless pipe | | L175 or A25 | 0,21 | 0,60 | - | 0,030 | 0,030 | - | - | - | | L175P or A25P | 0,21 | 0,60 | 0,045 | 0,080 | 0,030 | - | - | - | | L210 or A | 0,22 | 0,90 | - | 0,030 | 0,030 | - | - | - | | L245 or B | 0,28 | 1,20 | - | 0,030 | 0,030 | c,d | c,d | d | | L290 or X42 | 0,28 | 1,30 | - | 0,030 | 0,030 | d | d | d | | L320 or X46 | 0,28 | 1,40 | - | 0,030 | 0,030 | d | d | d | | L360 or X52 | 0,28 | 1,40 | - | 0,030 | 0,030 | d | d | d | | L390 or X56 | 0,28 | 1,40 | - | 0,030 | 0,030 | d | d | d | | L415 or X60 | 0,28e | 1,40e | - | 0,030 | 0,030 | f | f | f | | L450 or X65 | 0,28e | 1,40e | - | 0,030 | 0,030 | f | f | f | | L485 or X70 | 0,28e | 1,40e | - | 0,030 | 0,030 | f | f | f | | Welded pipe | | L175 or A25 | 0,21 | 0,60 | - | 0,030 | 0,030 | - | - | - | | L175P or A25P | 0,21 | 0,60 | 0,045 | 0,080 | 0,030 | - | - | - | | L210 or A | 0,22 | 0,90 | - | 0,030 | 0,030 | - | - | - | | L245 or B | 0,26 | 1,20 | - | 0,030 | 0,030 | c,d | c,d | d | | L290 or X42 | 0,26 | 1,30 | - | 0,030 | 0,030 | d | d | d | | L320 or X46 | 0,26 | 1,40 | - | 0,030 | 0,030 | d | d | d | | L360 or X52 | 0,26 | 1,40 | - | 0,030 | 0,030 | d | d | d | | L390 or X56 | 0,26 | 1,40 | - | 0,030 | 0,030 | d | d | d | | L415 or X60 | 0,26e | 1,40e | - | 0,030 | 0,030 | f | f | f | | L450 or X65 | 0,26e | 1,45e | - | 0,030 | 0,030 | f | f | f | | L485 or X70 | 0,26e | 1,65e | - | 0,030 | 0,030 | f | f | f | a) 0,50 % maximum for copper; 0,50 % maximum of nickel; 0,50 % maximum for chromium; and 0,15 % maximum for molybdenum.

Do not add Cu, Cr and Ni in case the grades are up to and including L360/X52

b) For reducing each 0,01% of carbon below the specified maximum concentration, 0,0.5% of manganese above the specified maximum concentration is permissible, up to a maximum of 1,65 % for grades L245 or B, but L360 or X52; up to a maximum of 1,75 % for grades >L360 or X52, but <L485 or X70; and up to a maximum of 2,00 % for grade L485 or X70.

c) The addition of vanadium and niobium should be 0,06 %.

d) The addition of vanadium, niobium and titanium concentrations shall be 0,15 %.

e) Unless differently agreed.

f) The total of the vanadium, niobium and titanium concentrations must be 0,15 %, unless differently agreed. |

Table 6

Requirements for the results of tensile tests for PSL 1 pipe

| Pipe Grade | Pipe body of seamless and welded pipes |

Weld seam of EW,

SAW and COW pip | Yield strengtha

R10,5

MPa(psi)

minimum

| Tensile strengtha

Rm

MPa(psi)

minimum

| Elongation

Af

%

minimum

| Tensile strengthb

Rm

MPa(psi)

minimum | | L175 or A25 | 175 (25 400) | 310 (45 000) | c | 310 (45 000) | | L175P or A25P | 175 (25 400) | 310 (45 000) | c | 310 (45 000) | | L210 or A | 210 (30 500) | 335 (48 600) | c | 335 (48 600) | L245R or BR

L245 or B | 245 (35 500) | 415 (60 200) | c | 415 (60 200) | L290R or X42R

L290 or X42 | 290 (42 100) | 415 (60 200) | c | 415 (60 200) | | L320 or X46 | 320 (46 400) | 435 (63 100) | c | 435 (63 100) | | L360 or X52 | 360 (52 200) | 460 (66 700) | c | 460 (66 700) | | L390 or X56 | 390 (56 600) | 490 (71 100) | c | 490 (71 100) | | L415 or X60 | 415 (60 200) | 520 (75 400) | c | 520 (75 400) | | L450 or X65 | 450 (65 300) | 535 (77 600) | c | 535 (77 600) | | L485 or X70 | 485 (70 300) | 570 (82 700) | c | 570 (82 700) | | a For the following highest grade, the variation between the specified minimum tensile strength and the specified minimum yield strength for the pipe body is provided in the table for intermediate grades.

b For intermediate grades, the specified least tensile strength for the weld shall be the exact value for the pipe body as determined using footnote a).

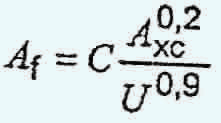

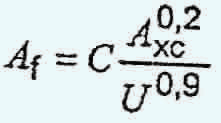

c The specific least elongation, Af expressed in percent and rounded to the nearest percent shall be determined using the equation  where C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

Axc is the applicable tensile test piece cross-sectional area, expressed in square millimetres (square inches), as follows:

----- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2(0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

------ for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2);

----- for strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2(0.01 in2); U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

| |

| | Chemical composition for PSL 2 pipe with 25,0 mm (0.984 in)

Table 5 | | Steel grade (steel name) | Mass fraction, based upon heat and product analyses

% maximum | Carbon equivalenta

% maximum | | C b | Si | Mn b | P | S | V | Nb | Ti | Other | CEiiw | CEpcm | | Seamless and welded pipes | | L245R or BR | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | c | c | 0,04 | e | 0,43 | 0,25 | | L290R or X42R | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | 0,06 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L245N or BN | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | c | c | 0,04 | e | 0,43 | 0,25 | | L290N or X42N | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | 0,06 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L320N or X46N | 0,24 | 0,40 | 1,40 | 0,025 | 0,015 | 0,07 | 0,05 | 0,04 | d,e | 0,43 | 0,25 | | L360N or X52N | 0,24 | 0,45 | 1,40 | 0,025 | 0,015 | 0,10 | 0,05 | 0,04 | d,e | 0,43 | 0,25 | | L390N or X56N | 0,24 | 0,45 | 1,40 | 0,025 | 0,015 | 0,10f | 0,05 | 0,04 | d,e | 0,43 | 0,25 | | L415N or X60N | 0,24f | 0,45f | 1,40f | 0,025 | 0,015 | 0,10f | 0,05 | 0,04f | g,h | as agreed | | L245Q or BQ | 0,18 | 0,45 | 1,40 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L290Q or X42Q | 0,18 | 0,45 | 1,40 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L320Q or X46Q | 0,18 | 0,45 | 1,40 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L360Q or X52Q | 0,18 | 0,45 | 1,50 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L390Q or X56Q | 0,18 | 0,45 | 1,50 | 0,025 | 0,015 | 0,07 | 0,05 | 0,04 | d,e | 0,43 | 0,25 | | L415Q or X60Q | 0,18f | 0,45f | 1,70f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 | | L450Q or X65Q | 0,18f | 0,45f | 1,70f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 | | L485Q or X70Q | 0,18f | 0,45f | 1,80f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 | | L555Q or X80Q | 0,18f | 0,45f | 1,90f | 0,025 | 0,015 | g | g | g | i,j | as agreed | | Welded pipe | | L245M or BM | 0,22 | 0,45 | 1,20 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L290M or X42M | 0,22 | 0,45 | 1,30 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L320M or X46M | 0,22 | 0,45 | 1,30 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 | | L360M or X52M | 0,22 | 0,45 | 1,40 | 0,025 | 0,015 | d | d | d | e | 0,43 | 0,25 | | L390M or X56M | 0,22 | 0,45 | 1,40 | 0,025 | 0,015 | d | d | d | e | 0,43 | 0,25 | | L415M or X60M | 0,12f | 0,45f | 1,60f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 | | L450M or X65M | 0,12f | 0,45f | 1,60f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 | | L485M or X70M | 0,12f | 0,45f | 1,70f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 | | L555M or X80M | 0,12f | 0,45f | 1,85f | 0,025 | 0,015 | g | g | g | i | 0,43f | 0,25 | | L625M or X90M | 0,10 | 0,55f | 2,10f | 0,020 | 0,010 | g | g | g | i | --- | 0,25 | | L690M or X100M | 0,10 | 0,55f | 2,10f | 0,020 | 0,010 | g | g | g | i,j | 0,25 | | L830M or X120M | 0,10 | 0,55f | 2,10f | 0,020 | 0,010 | g | g | g | i,j | 0,25 |

Table 5 ---chemical composition for PSL 2 pipe with 25,0 mm (0.984 in) (Continued)

| | a) Supported by product analysis. For smooth pipe with t > 20,0 mm (0.787 in), the equivalent limit of carbon shall be as agreed. The CEiiw limit applies if the mas fraction of carbon is more than 0,12% and the CEpcm limit applies if the mass fraction of carbon is less than or equal to 0,12%.

b) For reduction of every 0,0.1% for carbon below the specified maximum , an increase of 0,05% above the specified maximum for manganese is permissible, up to a maximum of 1,65 % for grades L245 or B, but L360 or X52; up to a maximum of 1,75 % for grades >L360 or X52, but < L485 or X70; up to a maximum of 2,00 % for grades L485 or X70, but L555 or X80; and up to a maximum of 2,20 % for grades >L555 or X80.

c) The total of the niobium and vanadium concentrations shall be 0,06 %, Unless other than agreed.

d) The total of the vanadium, niobium and titanium concentrations shall be 0,15 %.

e) Unless other than agreed, 0,50 % maximum for copper, 0,30 % maximum for nickel, 0,30 % maximum for chromium and 0,15 % maximum for molybdenum.

f) Unless differently agreed.

g) Unless other than agreed, the total of the niobium, vanadium and titanium concentrations shall be 0,15 %.

h) Unless differently agreed, 0,50 % maximum for copper, 0,50 % maximum for nickel, 0,50 % maximum for chromium and 0,50 % maximum for molybdenum.

i) Unless other than agreed, 0,50 % maximum for copper, 1,00 % maximum for nickel, 0,50 % maximum for chromium and 0,50 % maximum for molybdenum.

j) 0,004 % maximum for boron.

| | 9.2 Chemical composition

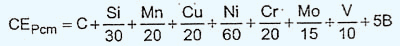

9.2.4 For PSL 2 pipe with a product analysis carbon mass fraction equal to or less than 0,12 %, the carbon equivalent, CEpcm, shall be determined using Equation (2):

where the mass fraction in percent are represented by symbols of the chemical elements (see Table 5).

It is not important for the product analysis to consider boron, if the heat analysis for boron is less than 0,000 5 % and the content of boron can be considered to be zero for the CEpcm calculation.

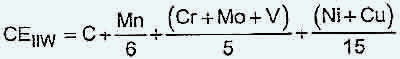

9.2.5 For PSL 2 pipe with a product analysis carbon mass fraction greater than 0,12 % the carbon equivalent, CEllw shall be determined using Equation (3):

where the mass fraction in percent are represented by symbols of the chemical elements (see Table 5).

NOTE: A derogation from the ISO rules for the presentation of chemical equations has been acknowledged for Equations (2) and (3) in deference to their wide utilization in the industry.

|

Requirements for the results of tensile tests for PSL 2 pipe

Table 7 |

| Pipe grade | Pipe body of seamless and welded pipes | Weld seam

of HFW, SAW and COW pipes | Yield strengtha

Rto,5b

MPa (psi) | Tensile strengtha

Rm

MPa (psi) | Ratioa,b,c

Rto,5/Rm | Elongation

Af

% | Tensile strengthd

Rm

MPa (psi) | | minimum | maximum | minimum | maximum | maximum | minimum | minimum | L245R or BR

L245N or BN

L245Q or BQ

L245M or BM | 245

(35 500) | 450 e

(65 300) e | 415

(60 200) | 760

(110 200) | 0,93 | f | 415

(60 200) | L290R or X42R

L290N or X42N

L290Q or X42Q

L290M or X42M | 290

(42 100) | 495

(71 800) | 415

(60 200) | 760

(110 200) | 0,93 | f | 415

(60 200) | L320N or X46N

L320Q or X46Q

L320M or X46M | 320

(46 400) | 525

(76 100) | 435

(63 100) | 760

(110 200) | 0,93 | f | 435

(63 100) | L360N or X52N

L360Q or X52Q

L360M or X52M | 360

(52 200) | 530

(76 900) | 460

(66 700) | 760

(110 200) | 0,93 | f | 460

(66 700) | L390N or X56N

L390Q or X56Q

L390M or X56M | 390

(56 600) | 545

(79 000) | 490

(71 100) | 760

(110 200) | 0,93 | f | 490

(71 100) | L415N or X60N

L415Q or X60Q

L415M or X60M | 415

(60 200) | 565

(81 900) | 520

(75 400) | 760

(110 200) | 0,93 | f | 520

(75 400) | L450Q or X65Q

L450M or X65M | 450

(65 300) | 600

(87 000) | 535

(77 600) | 760

(110 200) | 0,93 | f | 535

(77 600) | L485Q or X70Q

L485M or X70M | 485

(70 300) | 635

(92 100) | 570

(82 700) | 760

(110 200) | 0,93 | f | 570

(82 700) | L555Q or X80Q

L555M or X80M | 555

(80 500) | 705

(102 300) | 625

(90 600) | 825

(119 700) | 0,93 | f | 625

(90 600) | | L625M or X90M | 625

(90 600) | 775

(112 400) | 695

(100 800) | 915

(132 700) | 0,95 | f | 695

(100 800) | | L690M or X100M | 690

(100 100) | 840

(121 800) | 760

(110 200) | 990

(143 600) | 0,97 g | f | 760

(110 200) | | L830M or X120M | 830

(120 400) | 1 050

(152 300) | 915

(132 700) | 1 145

(166 100) | 0,99 g | f | 915

(132 700) |

| | Table 7 ----Requirements for the results of tensile tests for PSL 2 pipe (continued) | a) For intermediate grades, the deviation between the specified highest yield strength and the specified least yield strength shall be as given in the table for the following higher grade and the difference between the specified least tensile strength and the specified least yield strength shall be as given in the table for the following higher grade, For intermediate grades lower than Grade L555 or X80, the tensile strength shall be 760 MPa (110 200 psl). For medium grades more than grade L555 0r X80, the tensile strength that can be permissible maximally can be acquired by interpolation. For SI units, the value calculated can be round off to the nearest 5 Mpa. For USC units, the value calculated can be round off to the nearest 100 psi.

b) For grades >L625 or X90, Rp0,2 applies.

c) The mentioned limits apply for pipe with D >323, 9 mm (12.750 in).

d) For medium grades, the nominative tensile strength for the weld seam shall be the identical value as was determined for the pipe body using footnote a).

e) For pipe with D<219,1 mm (8.625 in), the maximum yield strength shall be 495 MPa (71 800 psi).

f) The specified minimum elongation, Af,shall be as determined using the following equation:

Where C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

A xc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

---- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2 ( 0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

---- for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2)

---- for strip test pieces, the lesser of a) 485 mm2(0.75 in2 ) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest_10 mm2 (0.01 in2 );

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

g) Lower Rto,5/Rm ratio values may be specified by agreement for L690 or X100 and L830 or X120 pipe.

| | |

| | |

|

| |

|

|

| | | | Contact Details | RELIABLE STEEL DISTRIBUTORS

GST : 27AACFR2900G1ZK | | 29-B, Nakoda Bhavan, Sindhi Lane, Charni Road, Mumbai - 400004, Maharashtra, India | | Fax : View Number | | Phone : View Number |

Accepts only Export inquiries

Accepts only Export inquiries

navas@reliablesteel.in navas@reliablesteel.in

|

| Mr. Navas Abdul

(Sr. Manager- Marketing)

Mobile : View Number | |

| |

| |

|

| |

|

|